As global environmental awareness continues to rise, the problem of plastic pollution is becoming increasingly serious, and the use of traditional plastic bags is gradually being restricted or even banned. In this context, compostable bags are as an environmentally friendly alternative, more and more companies and consumers favor.

Compostable bags are not only capable of rapid degradation in the natural environment, but also reduce the pollution of land and sea, which is an important part of realizing sustainable development. In the face of numerous compostable bag makers and manufacturers in the market, how to choose the right manufacturer to ensure product quality, environmental certification and supply stability is a concern for many businesses and purchasers.

In this article, we will introduce the definition of compostable bag, types of manufacturers, selection criteria, and the latest trends in the industry in detail to help you make informed purchasing and partnering decisions.

What is Compostable Bag?

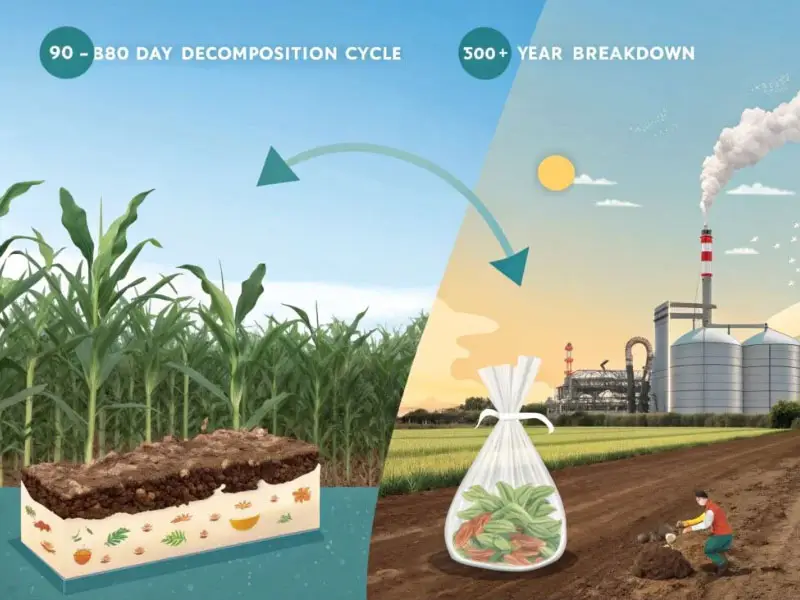

A compostable bag is a plastic bag that is able to decompose completely into water, carbon dioxide and biomass through the action of microorganisms in a specific composting environment within a certain period of time. These bags are usually made of plant-based materials and comply with international composting certification standards such as OK Compost and EN13432.

Differences from Traditional Plastic Bags

Traditional plastic bags are mainly made of petroleum-based polymers, which are difficult to degrade naturally and remain in the environment for a long time, causing serious pollution. Compostable bags, on the other hand, are made from renewable resources, such as polylactic acid (PLA), polybutylene adipate (PBAT), PHA, and other bio-based materials, which are capable of rapid degradation in industrial composting or home composting environments, greatly reducing the environmental burden.

Common Compostable Materials

PLA (Polylactic Acid): a bioplastic made from fermented corn starch or sugar cane that is transparent and compostable.

PBAT (Polybutylene Adipate Terephthalate): Flexible and often mixed with PLA to enhance bag performance.

PHA (Polyhydroxyalkanoates): produced by microbial fermentation, fully biodegradable and compostable.

Starch-based materials: corn starch and potato starch are used as raw materials, which are lower in cost and suitable for short-term use.

Certification Standards for Compostable Bags

Certification qualification is a key reference when choosing a qualified compostable bag manufacturer. Common certifications include:

- OK Compost (TÜV certified in Europe)

- EN13432 (EU standard for industrial composting)

- ASTM D6400 (US composting standard)

- Seedling Certification (International Compost Certification Mark)

These certifications ensure that the product can be effectively decomposed under specified conditions without causing secondary pollution to the environment.

What is Compostable Bag Maker

A compostable bag maker is usually a direct manufacturer or production factory, an entity that owns the equipment and processes for film blowing, printing, bag making, etc., and is able to produce a final bag from raw materials.

There are different types of players in the market:

Manufacturer / Producer: These are the core “Makers” with physical production facilities and technical capabilities. They can usually handle large orders, offer customization services, and may have a price advantage (cutting out the middleman). Finding a genuine compostable bag factory is the primary goal of many bulk buyers.

Supplier / Distributor: These companies may not produce compostable bags themselves, but rather purchase compostable bag products from one or more manufacturers and distribute them. They have the advantage of potentially offering lower minimum order quantities (MOQs), quicker deliveries due to local inventory, and easier customer service. They are a good choice for buyers with low demand or who need standard products quickly.

Brand Owner: Many of the best-known eco-bag brands on the market may not own factories directly, but rather use the OEM (OEM) or ODM (Original Design Manufacturing) model, commissioning qualified manufacturers to produce them. If you value brand reputation and service, you can work directly with the brand, but they still rely on a “Maker” behind them.

Equipment/Technology Provider: If your intent is to produce in-house, the “Maker” you are looking for is actually a supplier of compostable bag making machines or related production technology. or a supplier of related production technology.

So before you start your search, make sure you are clear: what do you need? Is it a factory-direct supply of large, customizable quantities or a standardized off-the-shelf supply of small quantities? Are you looking for a long-term strategic partner or just want to learn about compostable material technology? Clear objectives will greatly improve your efficiency in finding the right “Maker”.

Types of Compostable Bag Manufacturers

Large Industrial Manufacturers vs Small Customized Manufacturers

Large-scale Compostable Bag Manufacturer: with advanced production equipment and large-scale production capacity, able to meet the demand for bulk orders, with a rich product line and relatively stable prices.

Small Custom Compostable Bag Manufacturer: high flexibility, able to provide personalized customized services according to customer needs, such as custom printing, size specifications, etc., suitable for small and medium-sized enterprises or brand owners.

Chinese Manufacturers Vs International Manufacturers

Domestic Manufacturers: Usually have significant price advantage, short delivery lead time and quick response to local market demand.

International manufacturers: Mature technology, complete product certification, and strong brand influence, suitable for customers with high requirements for quality and certification.

Product Categories and Customized Services Offered by Manufacturers

Modern biodegradable bag makers (biodegradable bag manufacturers) not only produce standard shopping bags and garbage bags, but also provide diversified environmental protection packaging solutions, such as food packaging bags, courier bags, agricultural bags, etc., to meet the needs of different application scenarios. At the same time, more and more manufacturers support custom printed compostable bags to help brands enhance their image.

8 Factors in Choosing a Compostable Bag Maker

1.Certifications & Standards

This is the most important and confusing aspect of evaluating a compostable packaging supplier. “Compostable” is not a label to be used lightly; it must be based on rigorous scientific testing and authoritative certifications.

Core certifications.

- BPI (Biodegradable Products Institute): The most prestigious certification for the North American market, based on the ASTM D6400 standard (for industrial composting facilities). This is the gold standard when looking for a US or Canadian compostable bag manufacturer that carries the BPI certification mark.

- TÜV Austria (OK compost INDUSTRIAL / OK compost HOME): Widely recognized certifications in Europe and internationally. OK compost INDUSTRIAL is based on the EN 13432 standard (for industrial composting), while OK compost HOME means that the product can be decomposed at lower temperatures for home composting. OK compost HOME means that the product can be decomposed in a lower temperature home composting environment and is an important certification for home compostable bags.

- DIN CERTCO (Seedling Logo): Similar to TÜV Austria, the Seedling logo is also highly recognized in Europe based on the EN 13432 standard.

Verify authenticity: Always ask the manufacturer for a certificate of authenticity and verify its validity through the online database of official certification bodies. Be wary of vague terms such as “biodegradable” and make sure the product is clearly labeled as compostable and suitable for composting environments (industrial or home). Choosing a certified compostable bag manufacturer is the key to avoiding “greenwashing.

2.Materials & Technology

- PLA (Polylactic Acid): Mainly from renewable resources such as corn starch, good transparency, high hardness, usually requires industrial composting conditions.

- PBAT (Polybutylene Adipate/Terephthalate): petroleum-based, but fully biodegradable and compostable, flexible, often blended with PLA or starch.

- Starch Blends: Based on corn starch, potato starch, etc., blended with other compostable polymers, they are relatively low cost and have adjustable properties.

Matching performance: Different combinations of materials can affect the strength, toughness, barrier properties, shelf life, and ultimately the compostability and cost of the bag. Make sure the materials used by your manufacturer match your product needs and the composting infrastructure of your target market.

Manufacturing processes: Understand their film extrusion technology (affects film uniformity and strength), printing capabilities (e.g., environmentally friendly printing with water-based inks), and bag converting process (closure strength, bag shape versatility).

3.Product Range & Customization

Product Variety: Examine whether the manufacturer offers the type of compostable bags you need, such as: compostable trash bags, grocery bags, produce bags, apparel bags, mailer bags, and even agricultural film. bags, and even agricultural film.

Customization: Can the size, thickness (usually expressed in microns or mils), and weight capacity be adjusted as needed?

Printing and Design: Does it support multi-color printing? Can your logo and branding be accurately reproduced? Are design assistance services available? A strong custom compostable bags capability is an important aspect of a manufacturer's capabilities.

4.Production Capacity & Scale

Production Capacity & Scale: Find out the size of the plant, the number of machines, and the annual output. This relates to their ability to fulfill your orders, especially in large quantities.

Minimum Order Quantity (MOQ): This is especially important for SMEs. A high MOQ can be a barrier to cooperation.

Lead Time: How long does it take from order to shipment? Consistent lead times are critical to your supply chain management. Look for a partner that can provide scalable production to handle future growth.

5.Quality Control & Reliability

Quality System: Is the company certified to an international quality management system such as ISO 9001? Do you have a comprehensive Quality Assurance (QA) process?

Product Testing: Can you provide internal or third-party product performance test reports (e.g., tensile strength, puncture resistance, etc.)?

Customer Feedback: Check out online testimonials, customer case studies, or request testimonials.

Factory Audit: For important orders or long-term cooperation, consider conducting an on-site or third-party factory audit to assess the production environment and management level.

6.Geographic Location & Logistics

Shipping Costs & Times: A manufacturer's geographic location has a direct impact on shipping costs and transit times. Should I choose a local supplier or an international compostable bag manufacturer, such as a compostable bag factory in China or a producer in Vietnam?

Trade experience: If cross-border sourcing is involved, verify that the manufacturer has extensive international trade experience and is familiar with the export process, documentation requirements, and customs clearance.

7.Price & Cost-Effectiveness

Price Transparency: Get a detailed quotation and understand the price components. Be wary of low prices, which may be at the expense of quality or certification compliance.

Total Cost: Look beyond the unit price and consider the total landed cost of ownership (MOQ), freight, and possible duties.

Long-term value: For long-term, bulk purchases, explore whether volume discounts or better contract terms are available. Remember, the best option is good value for money, not the lowest price.

8.Corporate Sustainability Practices

Go beyond the product itself: An eco-friendly bag producer that is truly committed to sustainability should not only make products that are environmentally friendly, but also run its operations in a way that is environmentally friendly. For example, does it use renewable energy? Does it have a good waste management system?

Social Responsibility: Focus on their Corporate Social Responsibility (CSR) reports or practices in terms of labor rights and community contributions. Partnering with such a company will also enhance the image of your own brand.

How to Find Compostable Bag Manufacturers

Online B2B Platforms: Alibaba, Made-in-China, Global Sources

International platforms: Alibaba (Alibaba International), Made-in-China (Made-in-China), Global Sources (Global Sources) are popular platforms for finding manufacturers of compostable bags in Asia, especially China.

Regional/Specialized Platforms: Thomasnet (North American Industrial Sourcing Platform), Europages (European Business Yellow Pages), as well as a number of industry websites or directories focused on sustainable packaging.

Search engine optimization tip: “compostable bag manufacturer USA”.

Professional social networks: LinkedIn is a great place to find specific companies and connect with key people.

Trade Shows & Events.

Attend major packaging exhibitions, environmental technology expos or sustainability summits. A great opportunity for manufacturers to meet face-to-face, view samples on-site, make direct contacts and learn about the industry's latest bioplastics technologies.

Industry Associations & Networks.

Join one of the relevant sustainable packaging coalitions or environmental industry associations. These organizations often have membership directories and can provide industry insights and recommendations.

Industry Status and Market Trends

Global Compostable Bags Market Size and Growth Forecasts

The global biodegradable packaging market continues to grow rapidly as government controls on plastic products increase. The CAGR is expected to exceed 15% in the next five years.

Driven by Government Policies and Regulations

Several countries and regions have introduced plastic bag bans or restrictions to push companies to shift to eco-friendly packaging. For example, the European Union plans to completely ban single-use plastic bags in 2025, and several countries in North America and Asia are also developing similar regulations.

New Technology and Material Innovation

With technological advances in bio-based materials and composites, the performance of plant-based plastic bags continues to improve and the cost is gradually reduced, driving market penetration.

Opportunities brought about by consumers' rising environmental awareness

Modern consumers are more inclined to choose environmentally friendly products, and the adoption of compostable bags by companies not only meets regulatory requirements, but also enhances brand competitiveness.

Conclusion

Choosing the right compostable bag maker should not only focus on the price, but also comprehensively consider the certification qualification, product quality, production capacity and service level. With increasingly stringent environmental regulations and consumers' environmental awareness, the use of compostable bags has become an inevitable choice for sustainable development of enterprises.