As people become more environmentally conscious, sustainable packaging materials are gaining attention. Many companies are increasingly prioritizing green initiatives and are turning to biodegradable plastics.

Biodegradable and compostable plastics are currently popular in supermarkets and on e-commerce platforms. But do biodegradable plastics truly degrade? And are they truly environmentally friendly?

This article explains in detail what biodegradable plastic means. We'll cover the types of biodegradable plastic, its advantages and disadvantages, its composition, and how it's manufactured. We hope this will help you find sustainable, eco-friendly products.

What Is Biodegradable Plastic ?

Biodegradable plastics refer to plastics that are gradually decomposed into carbon dioxide, water, methane and inorganic salts by microorganisms (such as bacteria, molds, fungi, etc.) in natural environments (such as soil, sand, seawater, etc.) or under specific conditions (such as composting, anaerobic digestion, etc.).

How Biodegradable Plastics Break Down

Can be decomposed by microorganisms into harmless substances such as carbon dioxide and water in natural environments or under composting conditions.

Type of Biodegradable Plastic

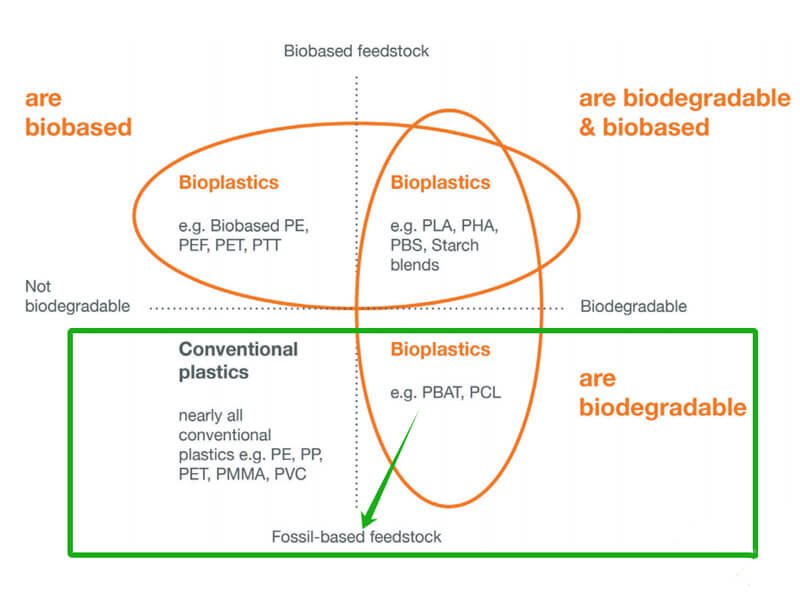

Based on the source of raw materials, biodegradable plastics can be divided into two categories: bio-based biodegradable plastics and petrochemical-based biodegradable plastics.

Bio-based biodegradable plastics:

Bio-based plastics are plastics derived wholly or partly from biomass. It is made from biomass such as corn and sugarcane through fermentation or chemical synthesis, and its carbon chain structure comes from renewable resources.

Including polylactic acid (PLA), polyhydroxyalkanoate polymers (PHAs), etc.

Petrochemical-based biodegradable plastics:

Petrochemical-based biodegradable materials are plastics obtained by chemically synthesizing petrochemical monomers. These materials include PBAT, PBS, PPC, PGA, etc.

Biodegradable Plastic Vs Compostable Plastic

| Aspect | Biodegradable Plastics | Compostable Plastics |

|---|---|---|

| Degradation Environment | Can decompose naturally or under composting conditions. | Must be degraded through a controlled composting process. |

| Decomposition Time | Can decompose in a few days to hundreds of years, depending on the material type. | Typically decompose within 90–180 days under composting conditions. |

| Product Requirements | Ultimately decompose into non-toxic substances such as carbon dioxide and water. | Must meet heavy metal limits and ensure decomposition does not inhibit plant growth. |

| Certifications | May not require specific certifications; varies by region and material. | Usually certified under standards such as EN13432, ASTM D6400, OK compost HOME. |

| Usage Scenarios | Used in products where general biodegradation is acceptable, like agricultural films. | Preferred for food packaging, bags, and other items intended for composting infrastructure. |

Applications of Biodegradable Plastic

- Industrial and Medical Products

In industrial production, biodegradable plastic bags offer excellent protection for everything from instruments to everyday items, while also reducing the environmental burden of waste.

In hospitals, biodegradable plastic bags, used for everything from medication bags to CT scan bags to waste bags, ensure the hygienic safety of medical supplies. They also naturally degrade after use, avoiding the environmental pollution associated with traditional plastic bags.

- Hospitality & Retail Use

The hotel industry is increasingly adopting biodegradable plastic bags, using them for guest room supplies, trash liners, and disposable items. Their environmental and practical features make them a top choice.

In retail environments like supermarkets and shopping malls, biodegradable bags are not only functional and aesthetically pleasing, but also enhance user engagement in environmental sustainability.

- E-commerce and Logistics

The rapid growth of e-commerce is driving a growing demand for environmentally friendly packaging. Biodegradable courier bags are popular in the logistics industry, reducing the environmental impact of online shopping plastic waste.

- Food and Agricultural Applications

Biodegradable takeout bags are replacing traditional plastic bags. Whether you're dine-in or ordering takeout, this convenient and sustainable packaging option aligns with eco-friendly dining.

In the agricultural sector, biodegradable mulch films are used to retain soil moisture and increase crop yields. Unlike traditional plastic films, they naturally decompose after use, preventing long-term soil contamination. Gardeners are also turning to biodegradable bags for packaging seeds, fertilizer, and tools, making gardening more environmentally friendly.

- Consumer Lifestyles

From pet food packaging to pet waste bags, eco-friendly alternatives are promoting healthier and more sustainable lifestyles for pets and their owners.

- Custom and Specialty Packaging

Biodegradable plastic bags can also be customized to meet specific business or brand needs. Companies can request bags in different sizes, colors, or prints, combining environmental responsibility with visual appeal and versatility.

Advantages of Biodegradable Plastics

Environmental Friendliness:

Biodegradable plastics are made from natural materials such as cornstarch, vegetable fats, and oils, which are renewable resources. Microorganisms can break these materials down into carbon dioxide, water, and biomass, which the environment can reuse. Unlike traditional plastics, biodegradable plastics do not release harmful chemicals into the atmosphere, making them a more sustainable option.

Reduction of Waste in Landfills:

Traditional plastics take hundreds of years to decompose, occupying valuable space in landfills. Biodegradable plastics decompose much faster, reducing the amount of space needed in landfills and potentially decreasing the need for new landfill sites.

Lower Greenhouse Gas Emissions:

The production of biodegradable plastics often requires less energy compared to traditional plastics. For instance, manufacturing corn-based polymers requires 65% less energy than producing similar polymers from petroleum. This reduction in energy consumption leads to fewer greenhouse gas emissions during production.

Non-Toxicity:

Traditional plastics are made using harmful by-products and chemicals, which can be a threat to the environment and life. They are likely to emit these harmful substances during the breakdown process. Biodegradable plastics, on the other hand, are manufactured using natural materials and do not release harmful chemicals into the environment, making them a safer alternative.

Versatility:

Biodegradable plastics are versatile and can be used in various applications, including packaging materials, disposable cutlery, and even medical implants. They can be molded into different shapes and sizes, making them highly adaptable to various needs.

Promotion of a Circular Economy:

Biodegradable plastics can promote a circular economy by reducing waste and creating a closed-loop system. In a circular economy, waste is minimized, and resources are reused and recycled. Biodegradable plastics can help to create a closed-loop system by breaking them down into natural components that can be used to make new products. This reduces the amount of waste in landfills and promotes a more sustainable system.

Bioplastics, Bio-based, Biodegradable, Oxo-plastics

| Category | Raw Material Source | Biodegradable? | Degradation Conditions | Examples |

|---|---|---|---|---|

| Bioplastics | Biomass or Petroleum | Partially biodegradable, partially non-biodegradable | Depends on specific material | PLA, PHA |

| Bio-based Plastics | Biomass (renewable resources) | Not necessarily biodegradable | Non-biodegradable or requires specific conditions | Bio-PE, Bio-PET |

| Biodegradable Plastics | Biomass or Petroleum | Biodegradable | Requires microorganisms, humidity, temperature, etc. | PLA, PBAT, PHA |

| Degradable Plastics | Biomass or Petroleum | Not necessarily biodegradable | Light, oxidation, or biodegradation | Photodegradable PE, Oxo-degradable plastics |

Biodegradable Production Processes and Raw Materials

Renewable Resources as Raw Materials

Biodegradable plastics are often produced from renewable resources, reducing reliance on fossil fuels. Common feedstocks include:

- Corn Starch: Used in the production of PLA and starch-based plastics.

- Sugarcane: Fermented to produce lactic acid for PLA synthesis.

- Vegetable Oils: Utilized in the production of certain PHAs.

Environmental Impact of the Production Process

The production of biodegradable plastics can have a lower environmental footprint compared to traditional plastics, especially when using renewable resources. However, factors such as land use for crop cultivation, water consumption, and energy use must be considered to ensure overall sustainability.

Comparison with Traditional Plastic Production

While biodegradable plastics offer environmental benefits, their production can be more resource-intensive and costly. Advancements in technology and economies of scale are expected to reduce these costs over time, making biodegradable options more competitive with traditional plastics.

What Are the Alternatives to Biodegradable Plastics?

| Material | Source | Key Features | Applications | Environmental Facts |

|---|---|---|---|---|

| 1. PLA (Polylactic Acid) | Corn, cassava starch | High transparency, compostable, low heat resistance (< 60°C) | Food packaging, disposable tableware, 3D printing filament | Industrial composting: degrades in 90 days; 70% lower CO₂ emissions than traditional plastic (Nature journal) |

| 2. PHA (Polyhydroxyalkanoates) | Fermented by microorganisms from sugars/oils | Fully biodegradable, oil- and water-resistant, high cost ($5–8/kg) | Medical sutures, controlled-release fertilizer capsules | Derived from renewable resources; degrades naturally |

| 3. Bamboo Fiber | Fast-growing bamboo (3–5 years maturity) | High strength (comparable to some engineering plastics), renewable | Household goods, textiles replacing plastic fibers | Short growth cycle; biodegradable |

| 4. Bagasse (Sugarcane Pulp) | Byproduct of sugarcane processing | Heat-resistant (up to 120°C), naturally biodegradable | Takeaway food containers, disposable cups and plates | Reuses agricultural waste; compostable |

| 5. PBAT (Polybutylene Adipate Terephthalate) | Synthetic biodegradable polymer | Flexible, improves PLA brittleness when blended | Compostable bags, packaging films | Degrades in soil within 6–12 months (European Bioplastics Association) |

| 6. Seaweed-Based Materials | Cultivated in seawater, no farmland needed | Grown in ocean, absorbs 1.5 tons CO₂ per ton grown | Transparent films, capsule shells | Sustainable marine farming; studied in Science (2022) |

| 7. Mycelium (Fungal Material) | Fungal mycelium + agricultural waste | Lightweight, flame-retardant, moldable | Furniture, construction materials | Fully biodegradable, made from low-impact raw materials |

Conclusion

Biodegradable plastics present a promising avenue for mitigating plastic pollution. When designed and managed appropriately, they can reduce the persistence of plastic waste in the environment. However, they are not a panacea and should be part of a broader strategy that includes reducing plastic consumption, enhancing recycling efforts, and developing alternative materials.

FAQ

Is Plastic a Renewable or Nonrenewable Resource ?

Plastic is a non-renewable resource.

Plastics are primarily made from fossil fuels like petroleum and are therefore non-renewable.

How Long Does It Take for Biodegradable Plastic to Decompose ?

Biodegradation time is affected by environmental factors such as temperature, humidity, and microbial activity.

- Composting conditions: Decomposition can be shortened to 2 days.

- Normal soil: 3-6 months.

- Marine environment: Some new plastics take 8 hours, while traditional plastics can take over 200 years.

Related Artical:

- Ultimate Guide of Biodegradable Certification

- How to Compost at Home: A Beginner’s Guide

- What Is Industrial Composting? A Comprehensive Guide

- What Are BPI Certified Compostable Bags Ultimate Guide

- Compostable Bags Vs Plastic Bags: Which Environmentally Friendly

Sources:

- wikipedia https://en.wikipedia.org/wiki/Biodegradable_plastic

- greenly.earth https://greenly.earth/en-gb/blog/company-guide/what-is-biodegradable-plastic

- greenly.earth https://greenly.earth/en-gb/blog/company-guide/what-is-biodegradable-plastic