Dogs are now part of our families and are part of our families. Dog trash bags are important for dog owners. Do you also want to know How dog poop bags are manufactured? Whether you’re a dog lover or a retailer interested in environmental sustainability, understanding the manufacturing process of compostable dog waste bags is important for you to make an environmentally smart choice.

In this article, we’ll walk you through the manufacturing process of biodegradable pet waste bags, from the raw materials used to the final product that arrives in your hands. We’ll also highlight the difference between plastic bags and compostable alternatives to help you choose the right type.

earth friendly dog poop bags

earth friendly dog poop bags

Types of Dog Poop Bags

Traditional plastic bags

Made from polyethylene (PE), a petroleum-based plastic. High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are commonly used.

Compostable dog poop bags

Eco-conscious manufacturers use plant-based materials, corn starch, PLA (polylactic acid), and PBAT (polybutylene adipate terephthalate). These materials are certified to decompose in industrial composting environments.

Biodegradable Dog Poop Bags

Biodegradable plastic bags break down faster than traditional plastic bags, potentially reducing long-term pollution. "Biodegradable" doesn't necessarily mean "eco-friendly."

Biodegradable dog poop bags may not be as eco-friendly as you think. Bags advertised as biodegradable may just be plastic, so "biodegradable" bags can leave behind microplastics or other harmful residues.

Difference between biodegradable and compostable dog poop bags

| Feature | Biodegradable Bags | Compostable Bags |

|---|---|---|

| Breaks down naturally? | Yes (but might take years) | Yes (within months in compost) |

| Leaves microplastics? | Often, yes | No |

| Certified? | Rarely | Yes (ASTM D6400, EN13432) |

| Eco-friendly? | Depends on material | Yes |

| Best disposal method | Landfill (but slow process) | Industrial compost facility |

Recommended articles:

Why include PBAT?

- Boost flexibility and strength

- Enable full biodegradation in composting conditions

- Make the bags more practical and affordable

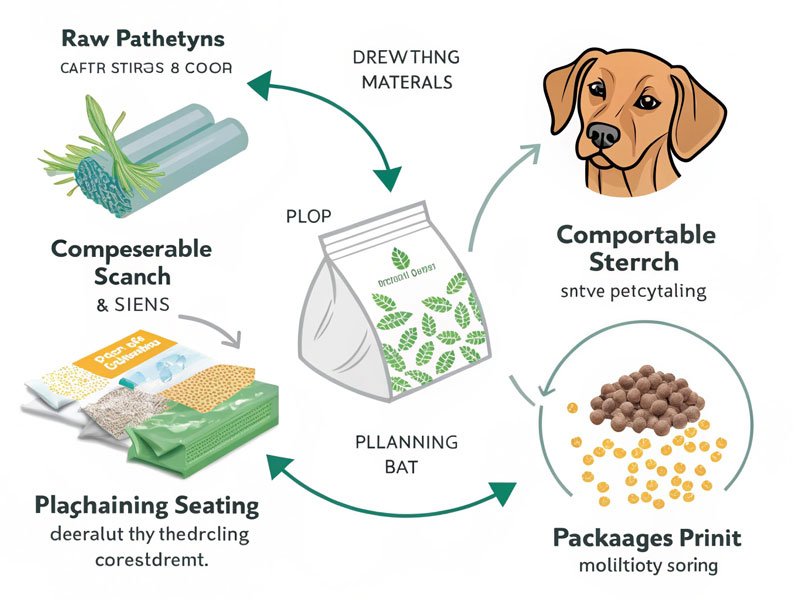

Dog Poop Bag Production Process

Dog Poop Bag Production Process

How Dog Poop Bags Are Manufactured

This article mainly focuses on compostable dog poop bags, so I won’t discuss plastic poop bags.

1. Raw material selection:

Natural biodegradable materials such as corn starch (Vegetable oil or potato starch), PLA (polylactic acid) and PBAT (polybutylene adipate terephthalate). These materials have good biodegradability and can be decomposed by microorganisms in the natural environment.

2. Extrusion molding

The granular or resin material is heated and melted by an extruder, extruded through a die to form a long and continuous film tube, called "blown film".

3. Cooling and shaping:

The film cools and hardens when it expands into a balloon-like bubble. It needs to be cooled and shaped to ensure that its shape is stable and not easy to deform.

At this stage, the manufacturer controls the thickness, width and strength of the compostable dog waste bags.

4. Printing: Brand and instructions

Logos, instructions for use and certification logos (such as ASTM D6400 or EN13432 for compostable products) are printed using environmentally friendly inks.

Retailers can customize bags with their own brands or private labels here.

5. Cutting and Sealing: Forming Individual Bags

The printed film is then passed through a machine that cuts the film to the required length (usually 9-13 inches per bag). Each bag is heat-sealed on the sides or bottom to ensure it is leak-proof. Some bags have gussets for increased capacity.

Some manufacturers also punch holes in the bags to facilitate tearing from the roll.

6. Rolling and Packaging

Rolled into compact bales (usually 15 bags per roll). Packed into cardboard or kraft boxes, or into retail-specific bags.

For eco-friendly brands, packaging may also be made of biodegradable or recyclable materials.

7. Quality Control

Each batch of products is quality-checked before shipment to ensure:

Proper size, seal strength, no defects or holes, odor control (for aromatherapy bags)

Eco-friendly brands also conduct compostability and non-toxicity testing.

why do dogs try to cover up their poop

why do dogs try to cover up their poop

Why Important to Understand the Dog Poop Bag Production Process

Understanding how dog poop bags are manufactured helps consumers and businesses alike make informed choices. If you're in retail, pet services, or waste management, sourcing bags made from certified compostable materials can reduce your environmental impact and appeal to eco-aware customers.

What Are Dog Poop Bags Good For?

Dog poop bags help keep things clean and hygienic. They prevent the spread of harmful bacteria and parasites found in dog waste, protecting both people and pets.

They’re important for the environment. Leftover dog waste can wash into waterways and pollute the environment. Using poop bags—especially compostable ones—helps reduce pollution and plastic waste.

Many cities require them by law. Dog poop bags help pet owners follow local regulations and avoid fines for not cleaning up after their dogs.

They’re convenient and easy to use. Most bags come in small rolls that fit in dispensers, making them great for walks, travel, or use in parks.

Eco-friendly bags support a sustainable lifestyle. Compostable dog poop bags reduce your carbon footprint and are a great choice for eco-conscious consumers and businesses.

They’re useful for more than just dogs. People also use them to clean cat litter, dispose of diapers, or handle waste during camping or road trips.

why do dogs cover up their poop

why do dogs cover up their poop

Conclusion

Dog poop bags may seem simple, but the process of making them is a delicate balance of material science, environmental responsibility, and practical design. From raw materials like polyethylene, to compostable blends like corn starch, PLA, and PBAT, to extrusion, printing, sealing, and packaging—each step is critical to creating a bag that is both efficient and environmentally friendly.

As demand for sustainable alternatives grows, more manufacturers are turning to compostable materials that break down safely without harming the planet. Whether you’re a consumer, retailer, or eco-conscious brand, understanding how these bags are made can help you make smarter, more environmentally friendly choices for your pets and the planet.

Recommended articles: