Struggling to grasp the dynamic compostable bag market? Growth brings complexity – new materials, regulations, and greenwashing risks. Making informed choices is vital for your business success and reputation.

Understanding the compostable refuse bag market requires knowing key trends (sustainability focus, regulations), product segments (materials like PLA/PBAT, capacities), critical certifications (BPI, TUV), regional variations (Europe vs. North America), and the challenges (cost, infrastructure) to make smart sourcing decisions.

The compostable biodegradable refuse bags market is evolving at a fast pace. As a compostable bag manufacturer working in this field for 16 years, I have witnessed these changes firsthand. It is critical for buyers like you to stay up to date with the latest information. Let's dive into the details you need.

What's driving the compostable bags market?

You see demand growing, but wonder what the underlying drivers and potential barriers are? Ignoring these factors could lead to missed opportunities or costly mistakes. Let's take a look at the big picture shaping this market.

Tighter plastic regulations and growing environmental awareness are driving the market. However, challenges such as higher costs compared to traditional plastics, performance limitations, and inconsistent composting infrastructure remain significant barriers to widespread adoption.

Understanding these dynamics helps you position your products effectively.

Key Market Trends

The shift towards sustainability is undeniable. Consumers and businesses increasingly prefer eco-friendly options. This drives demand for certified compostable products. We also see a push from circular economy initiatives, aiming to reduce waste and keep materials in use longer. Material innovation is constant, with new blends like PHA emerging alongside established options like PLA and PBAT, offering different performance characteristics.

Market Drivers

Governments worldwide are tightening rules on single-use plastics. This directly boosts demand for alternatives like compostable bags. Many authorities also promote composting through specific programs and infrastructure investments. Corporate Environmental, Social, and Governance (ESG) goals push companies to adopt sustainable packaging. Underlying all this is a growing public concern about plastic pollution and environmental health.

Market Constraints/Challenges

Cost Factor: Compostable materials are often more expensive than traditional plastics.

Performance Factor: Some compostable bags may have lower strength, shorter shelf life, or poorer heat resistance.

Challenges

Lack of widespread, accessible composting facilities, especially industrial ones. Consumer confusion about labeling (“compostable” vs. “biodegradable”) and proper disposal methods persists. Finally, the issue of “greenwashing” makes legal certification essential but adds complexity.

| Factor Type | Specific Examples |

|---|---|

| Trends | Sustainable packaging shift, Circular economy, Material innovation |

| Drivers | Regulations, Government initiatives, ESG goals, Environmental concerns |

| Challenges | Cost, Performance limits, Lack of infrastructure, Consumer confusion |

What are the product options in the compostable & biodegradable refuse bags market?

Are you overwhelmed by the wide variety of compostable bags on the market? Choosing the wrong material, size, or certification can result in poor performance, noncompliance, or unhappy customers. Understanding key market segments is essential for making smart purchases.

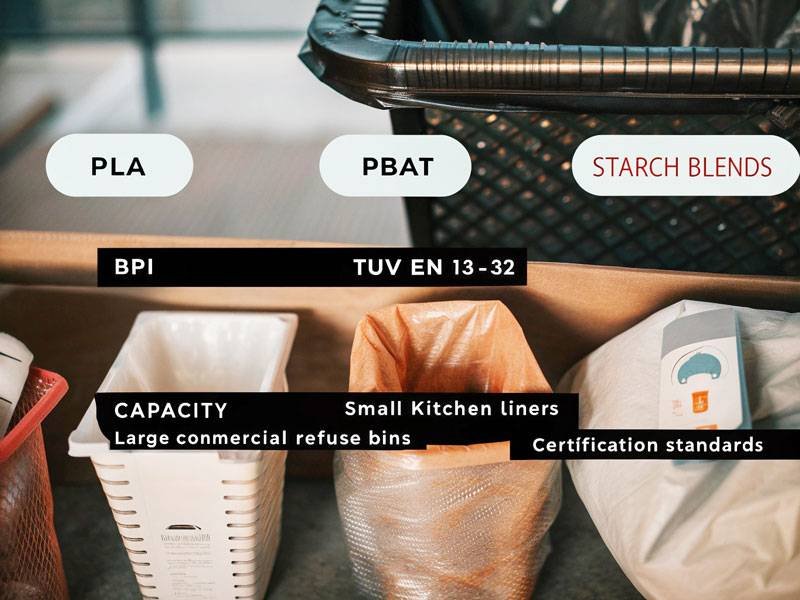

Compostable bags are segmented by material (e.g., PLA, PBAT, starch blends), capacity (from small kitchen liners to large commercial refuse bins), and most importantly, by certification standards (e.g., BPI, TUV EN 13432) to ensure they meet specific composting requirements.

Matching the right product to the right application and market is key. Let’s break down the pieces.

By Material Type

Different materials have different properties, costs, and composting behaviors.

- PLA (Polylactic Acid):Derived from corn starch, hard, suitable for some applications, but requires industrial composting.

- PBAT (Polybutylene Adipate Terephthalate):Based on fossil fuels, but fully biodegradable and compostable, flexible, often blended with PLA or starch.

- Starch Blends:Combines plant starch with polymers like PBAT to achieve flexibility and compostability. Commonly found in trash bags.

- PHA (Polyhydroxyalkanoate):Bio-based, degradable in a variety of environments, including the ocean (sometimes), usually more expensive.

- Other:Cellulose-based films are also used.

| Material | Key Characteristics | Composting |

|---|---|---|

| PLA | Rigid, Bio-based | Industrial |

| PBAT | Flexible, Blends well | Industrial/Home (some) |

| Starch Blends | Flexible, Cost-effective | Industrial/Home (most) |

| PHA | Bio-based, Broader degradation potential | Varies |

By Product Type/Capacity

- Small Capacity (<10L / <3 Gallons):For kitchen food scraps containers.

- Medium Capacity (10-50L / 3-13 Gallons):For standard household trash bins.

- Large Capacity (>50L / >13 Gallons):For larger residential trash bins, commercial or outdoor use.

- Specialty Bags:Designed for specific uses such as pet waste or yard clippings, often requiring specific strength or barrier properties.

Certification Standards

Certification verifies compostability claims under specific conditions. This is non-negotiable for market access and trust.

- ASTM D6400:North American standard specification for industrial compostability. The basis for BPI.

- EN 13432:European standard for industrial compostability. The basis for TUV OK Compost INDUSTRIAL.

- BPI Certified:Leading North American certification mark (using ASTM D6400).

- TÜV AUSTRIA OK Compost: European/global mark. Includes INDUSTRIAL and HOME variants (based on EN 13432 / EN 14995 or similar).

- AS 4736: Australian standard for industrial compostability.

How Do Regulations and Regions Impact Your Choices?

Can you sell the same compostable bag everywhere? Regulations, standards, and even composting infrastructure vary widely from region to region. Ignoring these local nuances can result in noncompliance, rejected shipments, and damaged brand reputation.

Compliance depends on meeting specific regional standards (e.g. EN 13432 in Europe, ASTM D6400-based in North America, AS 4736 in Australia) and understanding local composting capabilities (industrial vs. home availability).

As an OEM manufacturer shipping globally, we constantly navigate these differences for our clients. Here’s a brief overview:

Key Regional Differences

- North America (USA, Canada): Focus on BPI certification based on ASTM D6400 (industrial composting). State-level regulations (like California's) are also critical. Home composting certification is less common but growing. Infrastructure varies widely.

- Europe: EN 13432 is the key standard for industrial composting (TUV OK Compost INDUSTRIAL). TUV OK Compost HOME certification is also well-recognized for home compostable products. Regulations on single-use plastics are often stricter. Composting infrastructure is generally more developed than in NA, but still inconsistent.

- Asia-Pacific (including Australia): Australia has its own standards (AS 4736 for industrial, AS 5810 for home composting). China, Japan, and South Korea have developing regulations and standards. Market growth is strong, but infrastructure can be a limitation.

Regulatory Landscape Impact

Plastic bag bans and levies directly increase demand for compostable alternatives. Labeling laws are becoming stricter to prevent greenwashing – clear communication about certification and proper disposal is essential. Governments may offer incentives or mandates that favor certified compostable products, particularly in municipal waste programs.

Infrastructure Matters

The availability and type of composting facilities in your target market are crucial. If only industrial facilities exist, home compostable certification might be less relevant for refuse bags meant for municipal collection. Conversely, if targeting consumers with home composting bins, the 'OK Compost HOME' certification becomes valuable. Lack of infrastructure remains a bottleneck in many areas.

| Region | Key Standard(s) | Common Certification | Infrastructure Note |

|---|---|---|---|

| North America | ASTM D6400 | BPI | Variable, Industrial focus |

| Europe | EN 13432, EN 14995 | TUV OK Compost (IND/HOME) | More developed, varies |

| Australia/NZ | AS 4736, AS 5810 | ABA Verification | Growing, specific standards |

How Do You Choose the Right Manufacturing Partner?

Found potential suppliers, but unsure how to pick the best one? Choosing the wrong partner can lead to inconsistent quality, missed deadlines, compliance issues, and ultimately, harm your brand. It’s about more than just price.

Select a manufacturing partner based on their experience, valid certifications (BPI, TUV), robust quality control (like ISO 9001), customization capabilities, and a clear understanding of the complex compostable materials supply chain.

Finding a reliable OEM/ODM partner is critical for success in this market. Here’s what I recommend focusing on, based on our experience helping clients like you.

Experience and Specialization

How long has the manufacturer been working specifically with compostable materials? These materials behave differently than traditional plastics during extrusion and conversion. Look for proven expertise (like our 16+ years at ORIZON). Do they specialize in the type of bag you need (refuse bags, mailers, etc.)?

Certifications and Compliance

This is non-negotiable. Does the manufacturer hold certifications for their facility and, more importantly, can they produce products certified to the standards you need (BPI, TUV OK Compost INDUSTRIAL/HOME, based on EN 13432, ASTM D6400, etc.)? Ask for proof of current certifications and their scope. They should understand the testing and application process.

Customization and Quality Control

Can they meet your specific requirements for size, thickness, printing, and packaging? What are their quality management systems? Look for ISO 9001 certification as a baseline indicator of quality processes. Ask about their testing procedures for incoming raw materials and finished goods (e.g., checking strength, seals, dimensions). Our 20,000 sqm facility and 16 production lines allow for significant customization under strict QC.

Value Chain Awareness

A good partner understands the entire process, from sourcing certified raw materials to the final product's end-of-life. They should be knowledgeable about material properties, performance trade-offs, and regulatory requirements in your target markets. This ensures they can provide informed advice and reliable production.

Conclusion

Understanding the compostable biodegradable refuse bags market – its trends, products, regulations, and supply chain – is key to making smart purchasing decisions. Choosing certified products and reliable partners protects your brand and meets growing demand.