With the rapid development of the e-commerce industry, polyethylene bags have long become the first choice for the protection and transportation of packages and small items. If the size is not chosen properly, it will lead to excessive waste of packages and increase the cost of the enterprise. Then a question arises, how do you correctly measure the plastic bags for transportation?

As a supplier with 16 years of Biodegradable and compostable bags manufacturers, we will provide you with the correct method and specific reference sizes. I hope this blog post can help you reduce waste and improve efficiency.

Why Do We Need to Measure Polyethylene Bags Accurately?

The measurement of polyethylene bags is not only related to cost control and product aesthetics, but also directly affects transportation safety and compliance of e-commerce platforms.

- Reasonable reservation of redundant space helps to smoothly bag and seal, and reduce the breakage rate.

- Choosing the appropriate thickness (mil) can effectively improve the compression and puncture resistance, reduce returns and complaints.

- Strict and standardized size representation can avoid communication errors with suppliers and improve customization efficiency.

- Comply with platform and regulatory requirements to avoid unnecessary penalties and customs clearance troubles.

Common Poly Bag Types

Flat Poly Bags: Standard bag type without wrinkles, formed by two layers of film sealing three sides, mostly used for packaging clothing, loose parts, etc.

Gusseted Bags: There is an extended pleat space on the side of the bag, which has a stronger three-dimensional sense and is suitable for loading thicker or irregular objects.

Resealable or Ziplock Bags: The bag mouth is equipped with a self-sealing device, which is used in scenarios where repeated opening or moisture-proof sealing is required.

Express Bag Size Representation

Industry standard sizes are usually expressed as: Width x Length x Gusset, in inches or centimeters. Some bag types, such as flat bags, only require Width x Length. Bags with pleats need to add Gusset.

Other Related Information:

Mil: Used to indicate the thickness of the bag, 1mil=0.001 inch. The thicker the bag, the tougher and more durable it is.

Gusset: Refers to the space expanded on the side of the bag to facilitate loading wider items.

Seal: Different sealing processes affect the sealing and user experience.

Online Size Calculator

Poly Bag Size Calculator for Shipping

Enter your product's dimensions, and we'll recommend the perfect flat and gusseted poly bag sizes for you.

✅ Recommended [Flat Poly Mailer] Size

✅ Recommended [Gusseted Poly Bag] Size

*Disclaimer: These are recommended sizes and include ~1.5 inches of wiggle room. We strongly advise testing samples before making a bulk purchase.

Poly Bag Thickness Recommendations by Application

| Application Scenario | Recommended Thickness (mil) |

|---|---|

| Lightweight clothing | 1.5 – 2.0 mil |

| Standard electronic items | 2.0 – 3.0 mil |

| Heavy hardware, books | 3.0 – 4.0 mil |

| High-strength protection | 4.0 mil and above |

Step-by-Step: How to Measure a Poly Bag for Shipping

Measuring tools

Tailor Tape: Used to measure large and bent objects.

Steel Ruler: Used to measure shorter and hard objects.

Caliper: Used to accurately measure thickness and small parts.

Thickness Gauge: Used to specifically measure the thickness of polyethylene bags to prevent suppliers from making false labels.

1. Measurement of flat bags

Width: Open the bag and measure along the straight line of the bag seal from left to right to get the width of the bag.

Length: The distance from the bag mouth to the bottom seal. The extra "lip" outside the seal is not included in the total length. If in doubt, it is best to ask the manufacturer how to define the length to avoid cognitive bias.

Measurement steps:

Use a tape measure to straighten the bag to ensure that it is flat and wrinkle-free.

Measure the width along the opening direction.

Measure the length from the top of the opening to the bottom seal.

If the bag has a lip structure, only measure the main bag body.

Practical advice: The difference between the product size and the bag width is recommended to be about 1-2 inches to ensure smooth bagging and sealing.

2. Measurement of Gusseted Bags

Gusseted bags have an additional parameter called "pleat width" compared to ordinary flat bags. The method to obtain it is as follows:

Width: The width of the bag when it is flat, that is, the size of the sheet after it is unfolded.

Length: The straight-line distance from the bag opening to the bottom edge seal.

Gusset: Fully open the side pleats and measure the maximum unfolding distance. This value reflects the expansion capacity and volume space of the bag.

Measurement steps:

Put the bag flat on the table and unfold it naturally.

Measure the main width and length of the bag body, excluding the pleat part.

Open the side pleats with both hands and pull them to the maximum state to measure the pleat width.

The three data are summarized to obtain the complete size expression (width x length x pleat width).

Note: The pleats that are not fully opened are easily overlooked, resulting in the order bag type not matching the actual capacity.

3. Measurement of zipper bags or ziplock bags

Zipper bags are similar to ordinary flat bags, but you need to pay attention to the impact of the inner space and the seal structure on the effective loading space.

Measurement points:

The width is measured according to the main width of the bag.

The length is the actual distance from the bottom edge of the seal to the bottom of the bag, and the part above the zipper is not included.

If you need to load taller products, it is recommended to reserve 1 inch more space to avoid incomplete sealing due to the seal.

Suggestion: If the product is thick or has clear edges and corners, you can choose a ziplock bag with folds to prevent expansion from causing deformation of the bag or sealing failure.

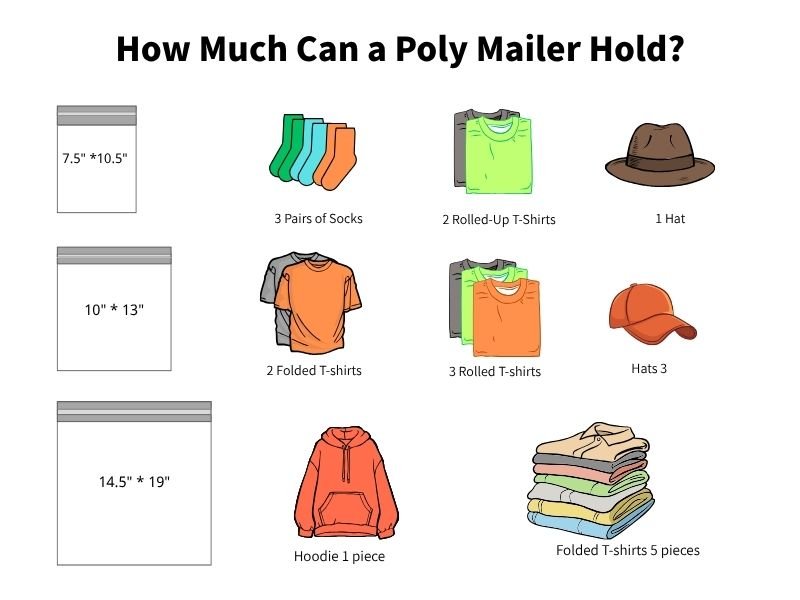

Poly Mailer Size Chart (Common Dimensions & Use Cases)

| Poly Bag Size (inches) | Typical Use |

|---|---|

| 6" x 9" | Jewelry, phone accessories |

| 9" x 12" | Small books, folded T-shirts |

| 10" x 13" | T-shirts, socks, small accessories |

| 12" x 15.5" | Shirts, thin hoodies, documents |

| 14.5" x 19" | Sweatshirts, pants |

| 19" x 24" | Coats, bulkier apparel |

| 24" x 24" | Blankets, pillows, soft items |

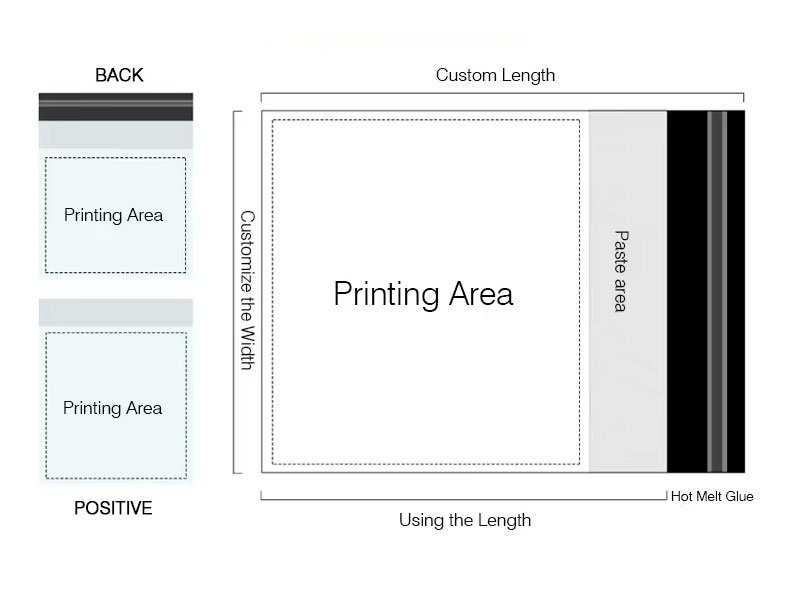

Why Do You Need to Customize the Size of Plastic Bags?

For many non-standard products, companies also want to add their own brand expression, then it is a wise decision to customize plastic bags. What are the options for customization:

- Perfect size, reduce space waste

- Pre-printed logo or pattern

- Eco-friendly or compostable materials

- Special features (bubble lining, tamper-proof seal, etc.)

- Before mass production, please be sure to let us know your required internal dimensions and request samples.

Plastic Mailing Bags Are Used For:

- Apparel

- Paper products

- Lightweight, soft items

- Products that don't require crush protection

If you're shipping fragile, hard, or bulky items, you'll need to use:

- Cushioned mailing bags

- Corrugated boxes

- Bubble mailing bags

In some cases, plastic mailing bags can be combined with cardboard liners for extra support.

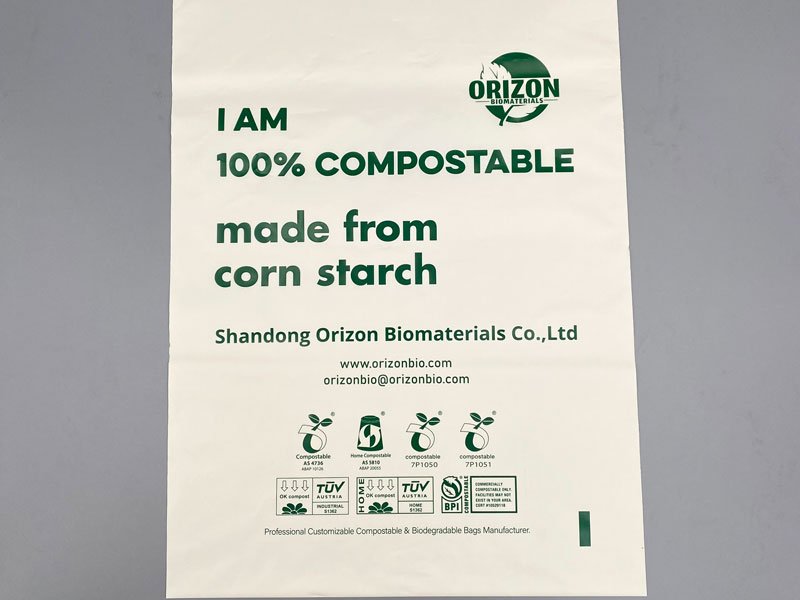

Compostable or Recyclable Trend

Many e-commerce brands are turning to eco-friendly plastic mailing bags made of compostable or recyclable materials. These options:

- Reduce plastic waste

- Meet sustainable development goals

- Attract environmentally conscious buyers

If you choose eco-friendly mailing bags, be sure to store them properly (in a cool and dry place) and use them before the expiration date.

How to Communicate with Express Bag Manufacturers and Suppliers

Clearly adopt the industry standard expression of "width x length x pleat width" and avoid semantically vague descriptions such as "width, height and thickness" and "spread all around".

If you need to customize special bag shapes or printing, confirm the shape of the actual loaded object in advance and ask the manufacturer for samples.

Timely communicate and confirm different measurement standards (inner diameter of the measuring bag vs. outer diameter of the bag) to prevent errors during delivery.

Ask if a product test report can be issued to ensure thickness and material compliance.

Packaging Regulations and E-Commerce Platform Requirements

- Common platform regulatory requirements

- Amazon FBA: There are some clauses for polyethylene packaging:

The thickness of transparent PE bags must be no less than 1.5mil; - Bags with a width greater than 5 inches must be printed with a warning label (the warning font must be greater than 10mm);

- The packaging bag must be sealed to prevent the product from being exposed;

- Products with vents or specific uses require further review.

- eBay, AliExpress, etc.: There are additional regulations on printing, thickness, and warning content. It is recommended to check the specific terms at the platform customer service center.

- Compliance labels and precautions

- The warning sign should be placed in a conspicuous position on the bag body and the font size should be consistent with the platform requirements.

- Special products (chemicals, powders, batteries, etc.) should be packaged in thickened bags according to category regulations, and inferior thin bags should not be used.

- Avoid using non-degradable and environmentally unfriendly materials. Some countries have banned ultra-thin plastic bags.

FAQ

What is a hem and why is the hem width measured?

The hem is the space that can be expanded on both sides of the bag. Measuring the hem width helps to load larger volume goods and make the selection more scientific.

How to measure the thickness of polyethylene bags?

You can use a thickness gauge to directly measure the material in the middle of the bag. Do not only refer to the supplier's nominal thickness to prevent actual discrepancies.

Why is there always a gap between the size of polyethylene bags and the size of products?

Because the user did not reasonably reserve redundant space for bagging, it is recommended to add 1-2 inches to each size and adjust the bag type.

What special issues should be paid attention to when using packaging bags for transportation?

Transportation is prone to extrusion and friction. It is recommended to use bags with sufficient thickness, hems and strong sealing. If anti-static, waterproof, and printed logos are required, custom requirements must also be stated.

Conclusion

For efficient and fast shipping, you need to measure your plastic bags correctly. The right size can better protect your products, reduce costs, and improve customer satisfaction. Whether you are shipping handmade products or expanding your online brand, it is worth taking the time to get the right measurements.

Follow the step-by-step method above, refer to the size chart, and if in doubt, test with samples before ordering plastic bags in bulk.

Need custom or compostable plastic bags?

If you are purchasing eco-friendly or custom sized plastic mailing bags wholesale, contact a trusted manufacturer like Orizon Biomaterials. We specialize in sustainable shipping solutions for growing brands.

Last updated: August 23, 2025 at 11:36 am